Product Center

服务热线

15814620810

·Rated power: 200W

·Resistance range: 3-15K

·Maximum accuracy: ± 5%

·Resistance technology: wire wound resistance

·Packaging material: Industrial 6063 aluminum material

·Packaging method: sand mold filling

·Installation method: fixed with screws

·Working temperature range: -55 ℃~275 ℃

·Dimensions: L=165mm, W=60mm, H=30mm

Application areas: cranes, servo motors, frequency converters

■ Product features

1. The resistor core adopts a high-temperature resistant ceramic flat tube, and the basic size of the ceramic is determined according to the shell size.

2. The resistance wire is uniformly wound with high-quality electric heating alloy wire, and the alloy wire grade and model are determined based on the resistance value.

3. Sealing material: Both ends are sealed with cement sand resin slurry (electronic insulation material), and when the cement material is semi dry, an aluminum plate is used to press and seal it tightly, so that the aluminum plate and cement material are integrated to prevent sand leakage.

4. Shell: Made of high-quality industrial 6063 aluminum material, the aluminum shell is anodized to a matte silver color, and can also be sandblasted or brushed according to customer needs.

5. The lead wire adopts UL AWM3122 white textile silicone rubber high-temperature wire (conventional temperature resistance of 200 degrees, maximum temperature resistance of 250 degrees), and the wiring standard is as follows:

1) Equipped with national standard 1.3 square white braided silicone rubber high-temperature wire (high-temperature wire model: UL AWM3122, wire structure of 65/0.16mm, wire outer diameter of 2.7mm) for rated current below 8A (inclusive) from 150W to 600W. Rated current 10 to 20A, equipped with national standard 2.5 square white braided silicone rubber high-temperature wire (high-temperature wire model: VDEH05SJ-K, wire structure 51/0.25mm, wire outer diameter 3.65mm). Rated current 25 to 35A, equipped with national standard 4-square-meter white braided silicone rubber high-temperature wire (high-temperature wire model: UL AWM3122, wire structure 56/0.30mm, wire outer diameter 4.3 mm). Rated current of 40 to 50A, equipped with national standard 6-square-meter white braided silicone rubber high-temperature wire (high-temperature wire model: UL AWM3122, wire structure of 84/0.30mm, wire outer diameter of 5mm).

2) 800W to 1200W (inclusive) and rated current below 10A (inclusive) are equipped with national standard 1.5 square white braided silicone rubber high-temperature wire (high-temperature wire model: UL AWM3122, wire structure of 30/0.25m, wire outer diameter of 3mm). Rated current 10 to 20A, equipped with national standard 2.5 square white braided silicone rubber high-temperature wire (high-temperature wire model: VDEH05SJ-K, wire structure 51/0.25mm, wire outer diameter 3.65mm). Rated current 25 to 35A, equipped with national standard 4-square-meter white braided silicone rubber high-temperature wire (high-temperature wire model: UL AWM3122, wire structure 56/0.30m, wire outer diameter 4.3 mm). Rated current of 40 to 50A, equipped with a national standard 6-square-meter white braided silicone rubber high-temperature wire (high-temperature wire model: UL AWM3122, wire structure of 84/0.30m, wire outer diameter of 5 millimeters).

6. The lead out wire can also use UL 1322 braided PTFE high-temperature wire (conventional temperature resistance of 200 degrees, maximum temperature resistance of 250 degrees)

7. The wiring terminal adopts cold pressed all copper terminal, which is divided into RV series (0-type terminal), SV series (open terminal), FD series (spring terminal), DB V series (flat plug terminal), RNB series (round bare terminal), etc. The matching standards are as follows:

1) National standard 1.3 to 1.5 square lines: Choose from nine options: RV1.25-4mm, RV1.25-5mm, SV1.25-4mm, SV1.25-5m, SV1.25-6m, RV1.25-8mm, FD2-250mm, FDD2-187m, DBV2-14mm.

2) 2.5 square meters according to national standards: RV2-6m, RV3.5-6m (black cover, thickness 0.6mm), RV3.5-6mm (black cover, thickness 1.0mm according to national standards), FDD2-250mm, FDD2-187mm, DBV2-14mm. Choose one of the six options.

3) 4 square lines according to national standards: RV3.5-6m (black sleeve, thickness 0.6m), RV3.5-6m (black sleeve, thickness 1.0mm according to national standards), RV5.5-8mm (blue sleeve, thickness 0.8mm), choose one of them.

4) 6 square lines according to national standards: RV5.5-8mm (blue sleeve, thickness 0.8mm), RNB8-8mm (circular bare end, thickness 1.2mm according to national standards, using 8-10 blue sleeves), choose one of them.

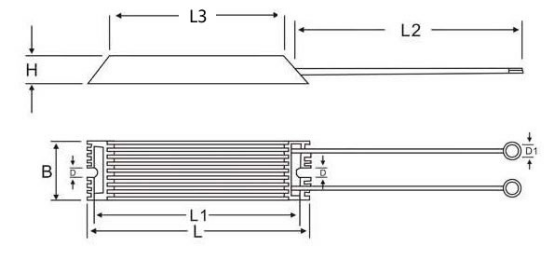

■ Specifications, dimensions, and technical specifications

◆ Specifications, dimensions, and units of measurement: mm

|

code |

Rated power (W) |

External dimensions |

Installation distance |

Installation aperture |

Wiring aperture |

Exposed wire length |

Resistance range |

|||

|

L (base length) |

L (face length) |

B |

H |

|||||||

|

RXLG |

200 (large size) |

165 |

125 |

60 |

30 |

150 |

5.5 |

4 |

165 |

3~15K |

*Note: The dimensions are for reference only. Specific dimensions and selection need to be consulted. Allowable deviation of resistance value (%): ± 5% ± 10%, withstand voltage (V): 2000.

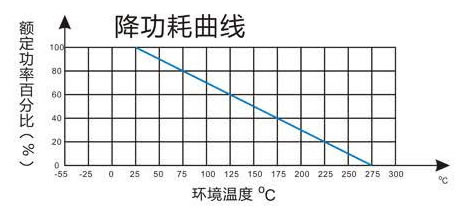

■ Product power consumption reduction curve chart

Customer selection, for exampleRXLG 200W 50 Ω± 5%, model: RXLG-200-50RJ-L; Low inductance, add the letter N to the model, for example: N RXLG-200-50RJ

|

RXLG |

200 |

50R |

J |

L |

|

code |

Rated power |

Resistance value |

accuracy |

Installation method |

|

RXLG series (trapezoidal aluminum shell) |

50=50W 100=100W |

0R1=0.1Ω 100R=100Ω |

F=±1% G=±2% H=±3% J=±5% K=±10% |

T=Terminal L=Introduction |

■ Suggestions for using resistors

It is best to leave 1.5 times the power margin for resistors in circuits. For example, if the voltage in the circuit is 100V and the current is 0.01A, the calculated power is P=100 * 0.01=1W. At this time, a resistor of 1W cannot be used, and 1 * 1.5=1.5W is calculated. Without a 1.5W resistor, a 2W resistor is needed